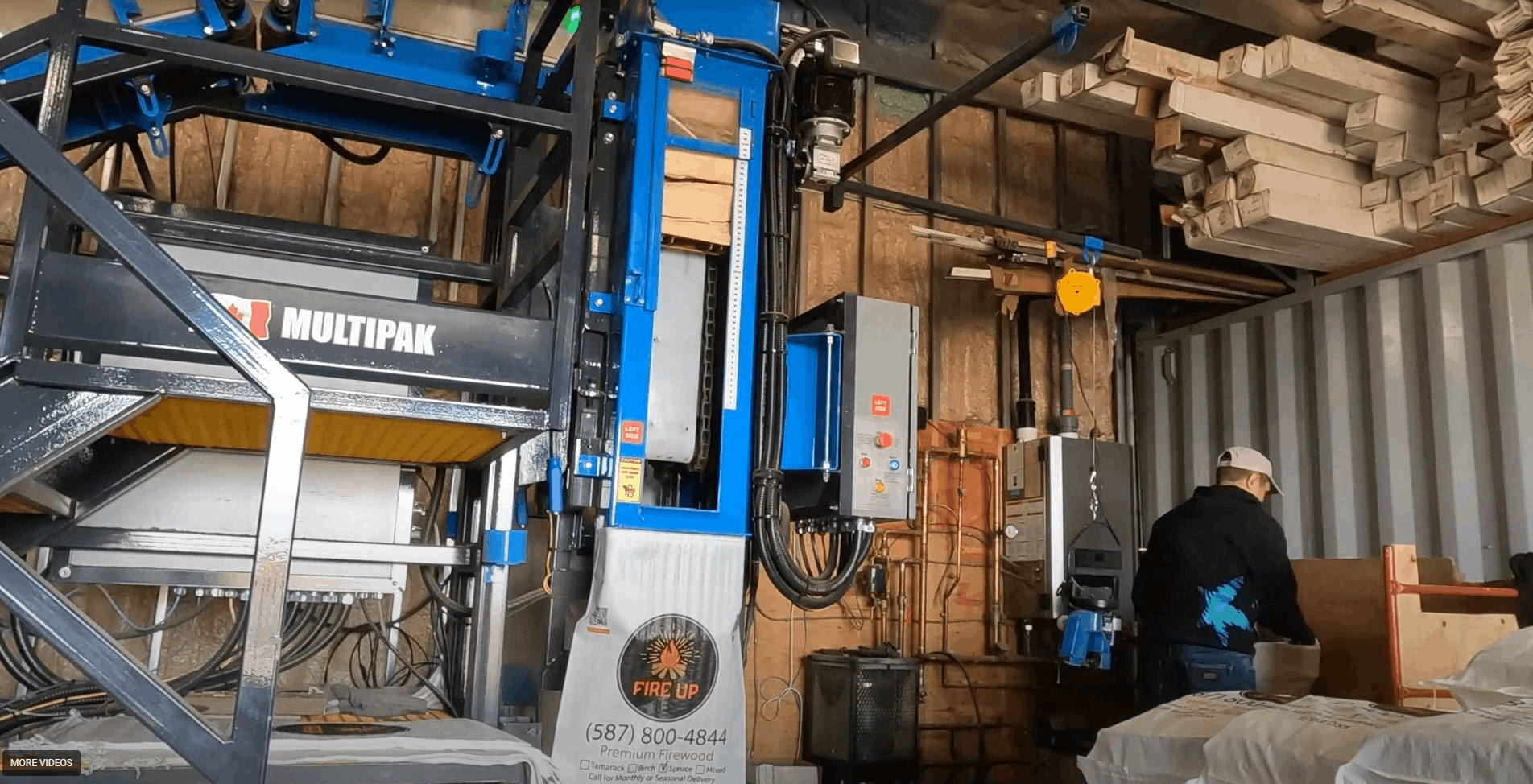

Designed specifically for firewood operations, AND “Y” Knot replaces labor-intensive packaging processes with true automation—delivering consistent, industrial-grade performance in demanding production environments.

Every step of the process is designed to reduce touchpoints, increase speed, and improve operational efficiency—turning processed firewood into packaged product faster and more consistently.

Engineered specifically for firewood packaging—not a repurposed or generic system.

Reduces manual labor rather than merely assisting it, freeing crews for higher‑value work.

Minimizes re‑stacking, lifting, and unnecessary movement throughout the packaging process.

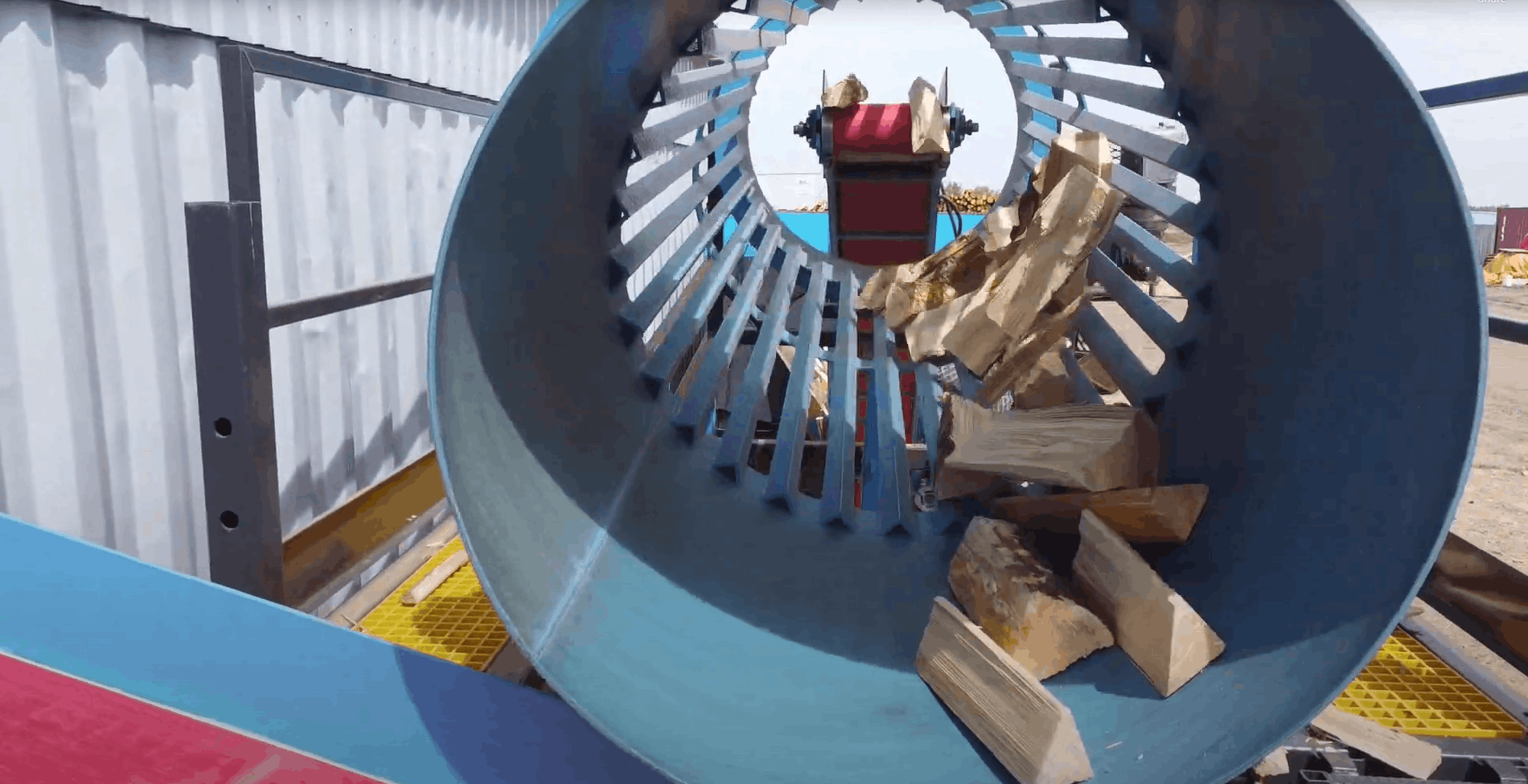

Built to withstand demanding environments and high production volumes.

Delivers uniform, repeatable packaging for improved presentation and downstream handling.

Supports growth without proportional increases in labor or complexity.

This approach delivers measurable gains without the integration challenges or overhead of generic robotic systems.

Refined through real-world feedback and built on practical engineering principles, AND “Y” Knot is designed for long-term operational efficiency and dependable performance across production seasons.

CAD renders, machine detail close-ups, and engineering diagrams reflect the precision and intent behind every component of the system.

If you’re looking to modernize your firewood packaging operation and reduce labor dependency, AND “Y” Knot delivers automation designed specifically for your industry.