Designed and engineered in North America, AND “Y” KNOT is built to meet the real demands of modern firewood producers, delivering reliable performance, durable construction, and long-term serviceability you can trust.

AND “Y” KNOT is purpose-built for industrial firewood operations, delivering dependable automation, consistent performance, and rugged construction designed for continuous, high-volume production.

Designed to eliminate manual bottlenecks, AND “Y” KNOT reduces labor requirements while accelerating packaging speed—helping producers shorten lead times and scale output with confidence.

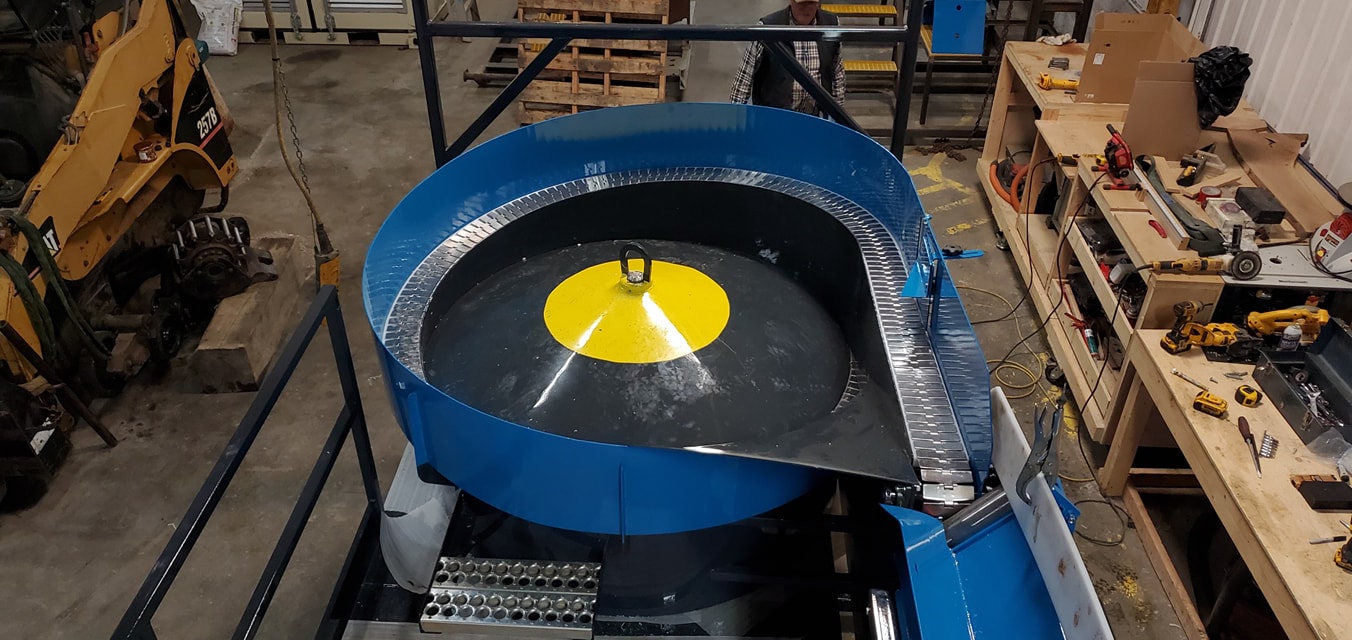

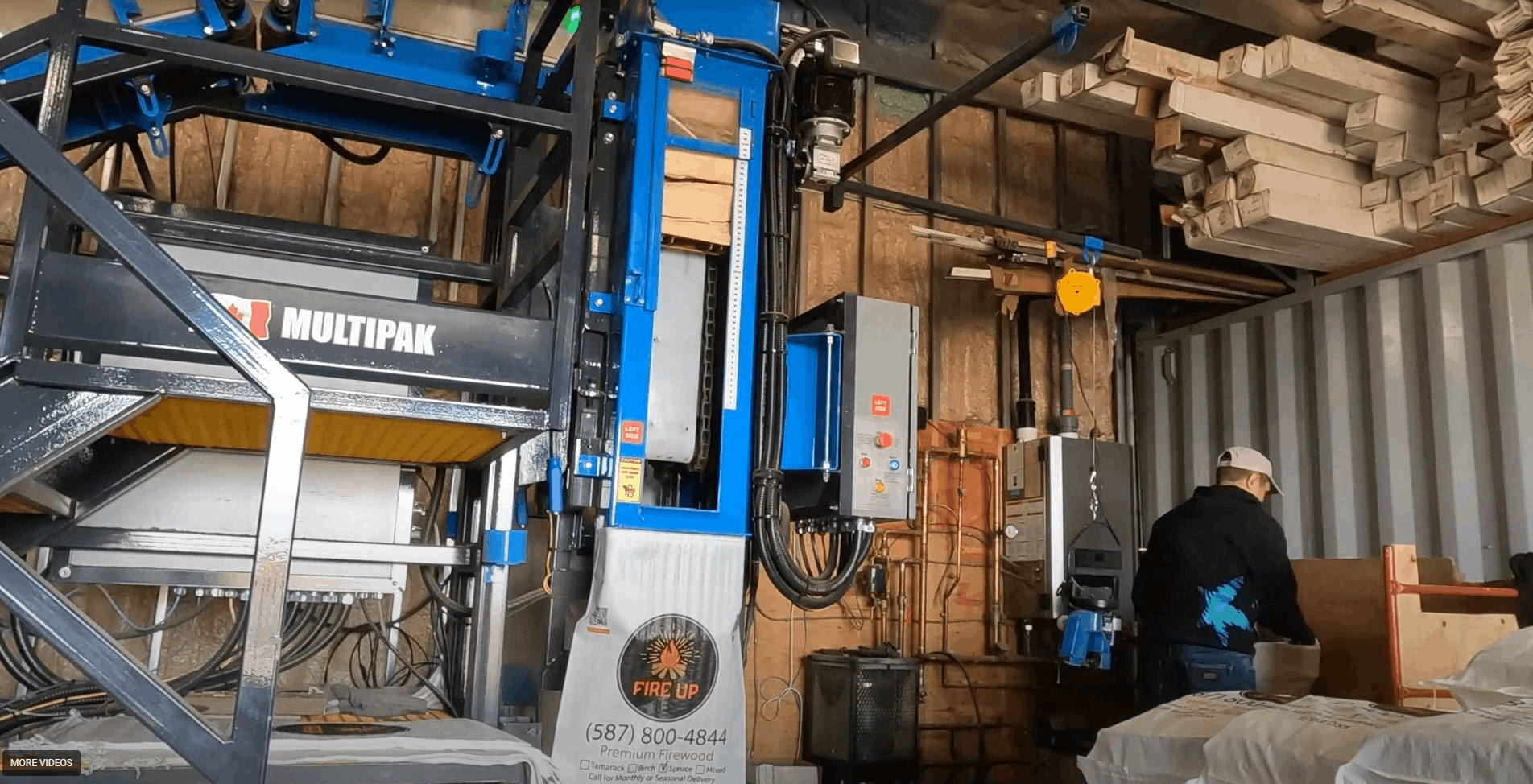

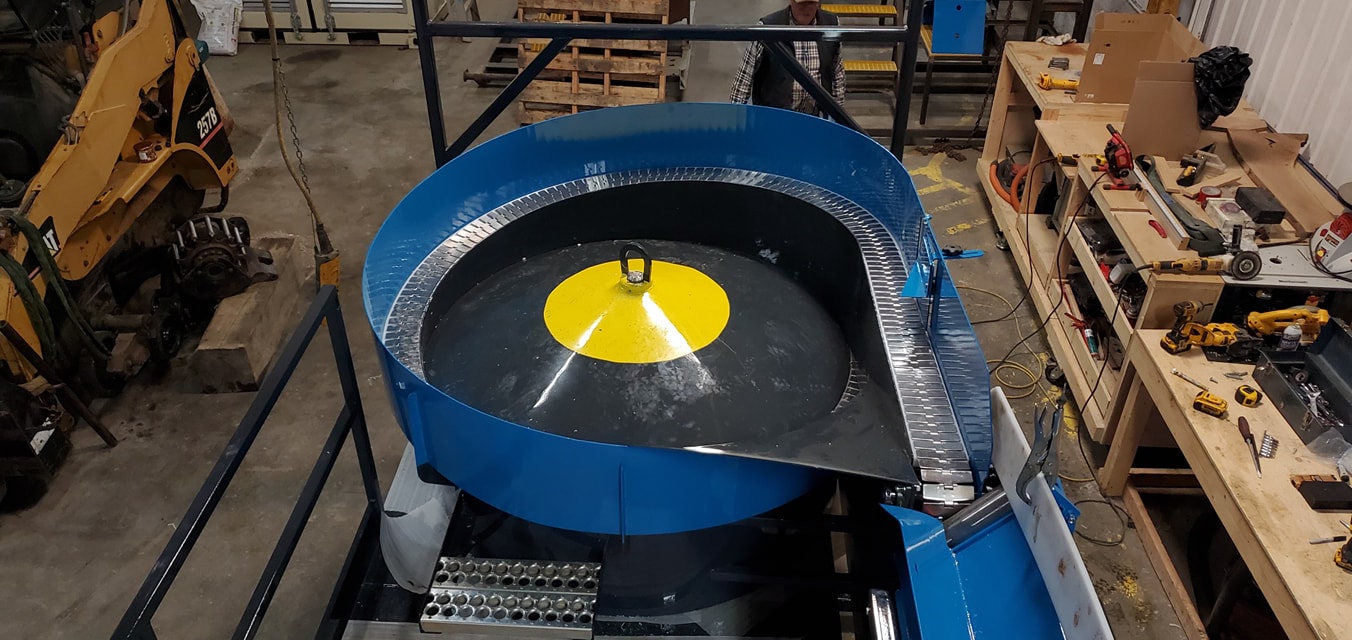

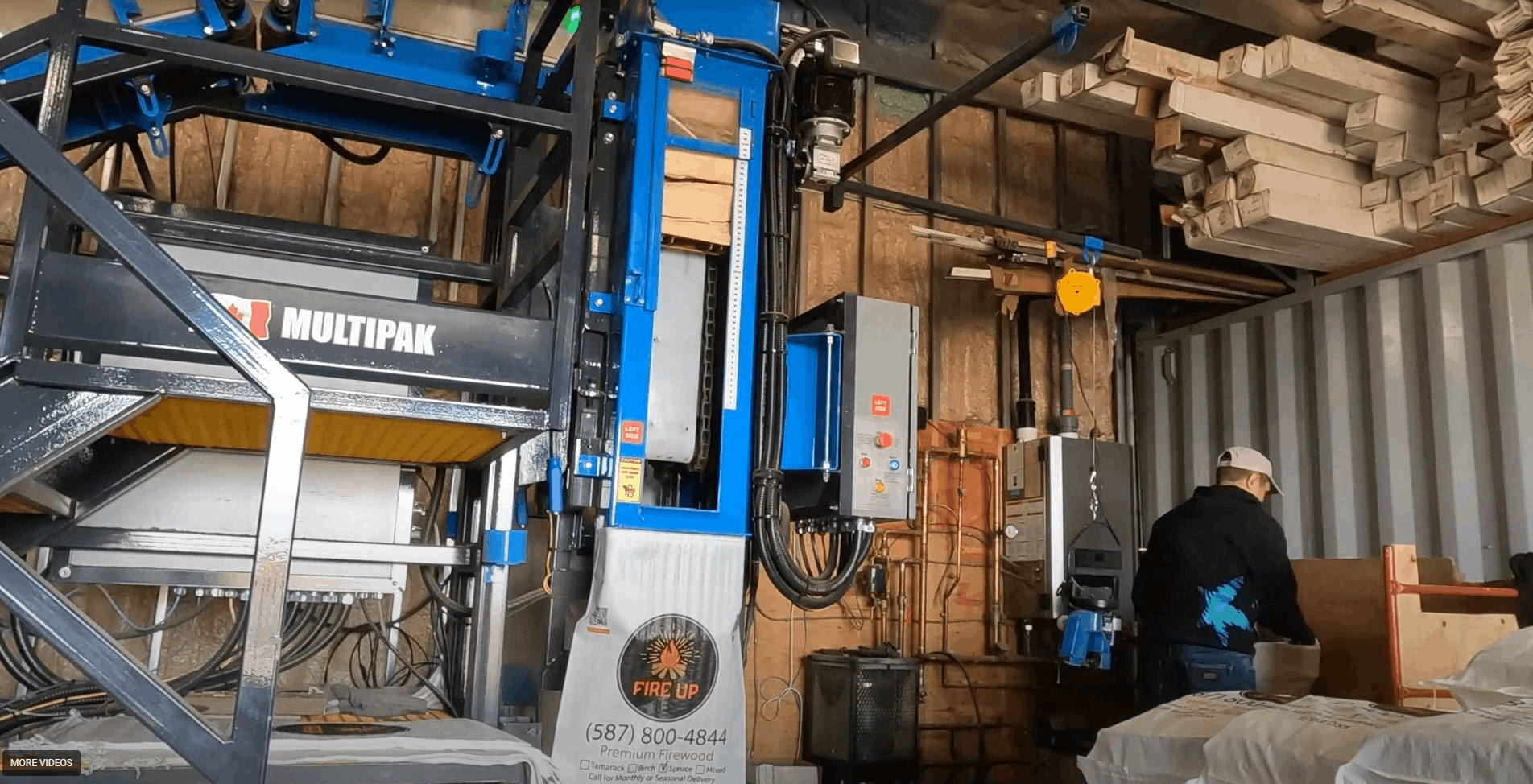

The MULTIPAK Automated Firewood Packaging System by AND “Y” KNOT automates the most time-consuming parts of firewood packaging, allowing producers to:

Engineered specifically for firewood packaging—not a repurposed or generic system.

Reduces manual labor rather than merely assisting it, freeing crews for higher‑value work.

Minimizes re‑stacking, lifting, and unnecessary movement throughout the packaging process.

Built to withstand demanding environments and high production volumes.

Delivers uniform, repeatable packaging for improved presentation and downstream handling.

Supports growth without proportional increases in labor or complexity.

Runs mesh bags, polypropylene bags, plastic bags, and boxes or cartons without needing modifications, keeping uptime high and changeovers off the schedule.

By automating packaging and enabling production closer to delivery schedules, the MULTIPAK system minimizes excess bulk storage, reduces tied-up capital, and improves overall inventory turnover.

Every step of the process is designed to reduce touchpoints, increase speed, and improve operational efficiency—turning processed firewood into packaged product faster and more consistently.

Package into mesh bags, polypropylene bags, plastic bags, and boxes or cartons without adjustments or changeovers, so you can switch formats on demand and keep production moving.

The MULTIPAK Automated Firewood Packaging System by AND “Y” KNOT automates the most time-consuming parts of firewood packaging, allowing producers to:

Scale production without scaling labor costs.

Add downstream value through efficient packaging.

Increase throughput and reduce bottlenecks.

Ensure consistent, high-quality packaged firewood supply.

Packaging has always been the bottleneck in our operation. AND ‘Y’ KNOT was the first machine we’ve seen that actually addresses that problem instead of just assisting it. The automation is practical, well thought out, and clearly designed by people who understand the firewood industry

Western Canada

What stood out immediately was that AND ‘Y’ KNOT reminded us less of a generic packaging machine and more of a purpose-built solution. It’s designed around workflow, not workarounds. That makes a real difference on the production floor.

Wood Products Facility

From an engineering perspective, the AND ‘Y’ KNOT system is refreshingly straightforward. It’s built for reliability, not complexity, and that’s exactly what industrial operations need—especially during peak season.

Industrial Equipment Consultant

We’ve looked at multiple packaging options over the years, but most required adding labor as volume increased. AND ‘Y’ KNOT was the first solution that made us feel confident we could scale packaging without scaling headcount.

Firewood Supply Company

If you’re looking to modernize your firewood packaging operation and reduce labor dependency, AND “Y” KNOT delivers automation designed specifically for your industry.