USA Patent Number 11,465,792

USA Patent Number 12,006,079

Canadian Patent 3,088,030

European Union Patent Pending

Australia Patent Pending

The And “Y” Knot Firewood Packaging Machine reduces packaging time and handling requirements associated with firewood packaging and reduces lead time and storage needs of packaged product prior to prime selling seasons. Traditional manual firewood packaging is a physically taxing process that makes it difficult to retain employees, because 87% of the time preparing firewood for client use is spent packaging.

A single person is capable of making 1 bag/package in approximately 2 minutes. The machine is capable of making 3-4 bags/packages in 1 minute.

System Features

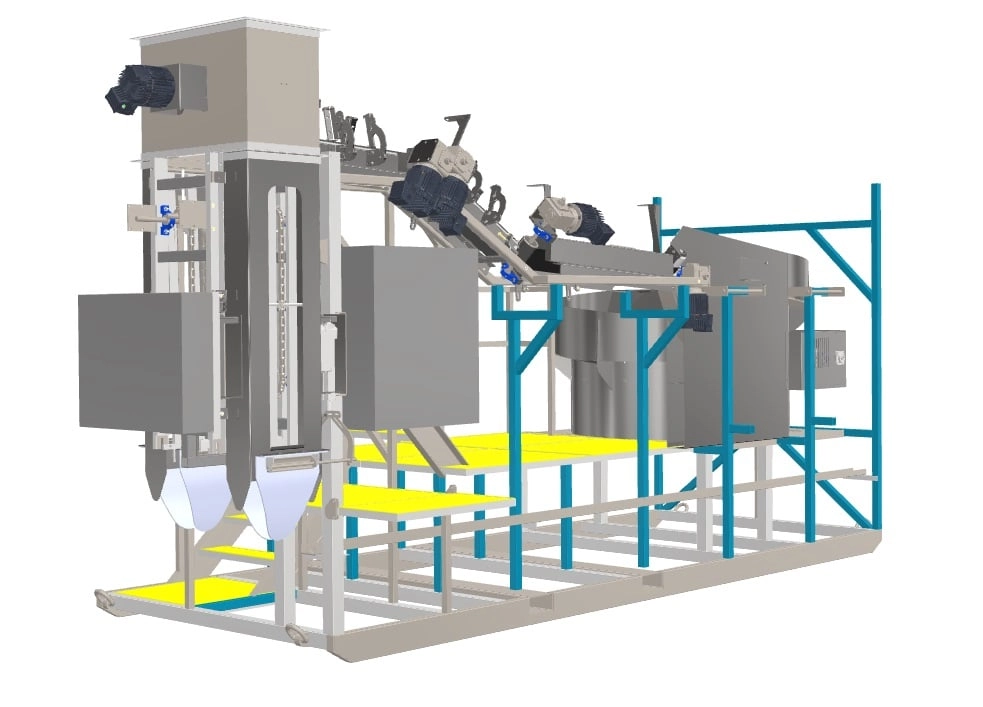

- All electric driven low amperage draw

- Single Phase 125/250V 30 Amp power @ 60HZ (Adjustable for Country Specific applications)

- HMI Controlled touch screen

- CSA and ULC Certified

- Multiple strategically positioned Emergency Stop Controls (ESD Switches)

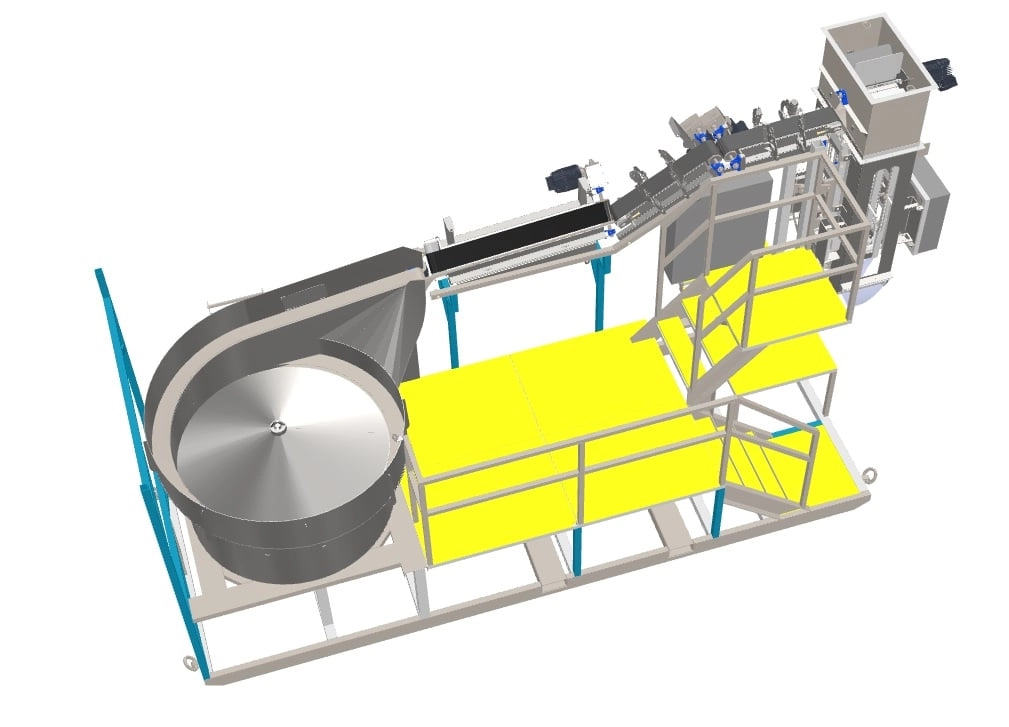

Feed Hopper

- 4 Cubic Meter Hopper is large enough to hold approximately 1 hour of packaging material

- Electrically driven and sensor controlled

Disc Cleaner

- Continuously running electrically driven and adjustable speed control

- 6 Foot long rotating Disc Cleaner to remove debris from packable material

- 8 Foot long outfeed conveyor to move package material to turntable

60” Rotating Turntable

- Sensor controlled feed system to provide smooth continuous flow of material

- Aligns material in proper orientation

Feeder Chain

- Elevated circular feed chain to pick up aligned material with adjustable material profiler to maintain continuous single file material feed

V Conveyor

- Smooth continuous rotating conveyor to maintain continuous material train like flow

Angled Conveyor

- Sensor controlled positive grip start/stop upward motion conveyor

In Feed Conveyor

- Sensor controlled positive grip forward/reverse high speed motion infeed conveyor with automatic unjamming feature built in.

Dual Packaging Head

- Heads designed from 8″ to 16″ (20cm to 40cm) long package material as per customer request

- Single or dual operator capable

- Multiple Elevator Platforms for Loading different package size material

- Fully automated packaging head to allow two different packaging styles(Carton or Bag) interchangeable

- Separate fully automated volume controlled packaging chambers

- Sensor controlled selector wheel to move material to desired packaging chamber

- Automatic elevated controlled material shelf to eliminate material drop and rotation

- Operator controlled package fill function

- Operator controlled bag package clamping system and or carton platform support system

Reduce the need to tie up cash in inventory

Reduce the cost of maintaining inventory

Increase the client’s ability to respond to market needs

Significantly reduce labour costs, injuries and insurance costs

Automate Your Production:

– 3-4 bags per minute

– Designed to package wood in bags and cardboard boxes

– Will package lengths from 8” to 16”

– On demand – Inventory cost savings

– Fully automated electronic operating systems

– Remotely adjustable

– Ergonomically designed to reduce physical labour and muscle strain

– Advanced safety features

– Requires very little training

– Consistent quality packaging

– Robust construction

– Simple maintenance, very little maintenance time required

– Dual bagging heads to enhance production time

What’s Included?

– Company representative or agent present at pick-up and start up

– All required components for full operation

– All operations and functions are tested and operated extensively before shipping

– Assembly instructions (minimal assembly required)

– Ready for immediate use with your wood and packaging materials

– One year manufacturing and parts warranty for normal operation

– Operating and parts manual

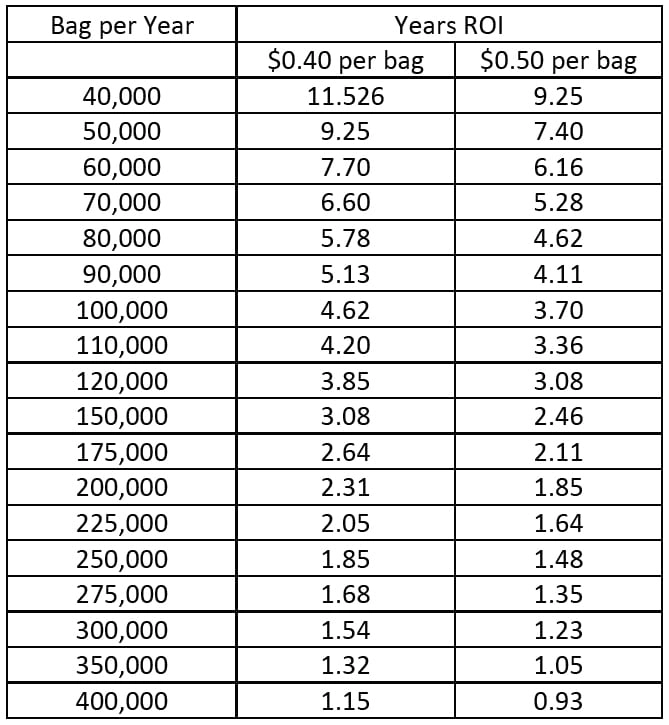

These calculations are based on approximately either $0.40 to $0.50 per bag goes to initial investment of machine.

Automated Firewood Packaging Machine Specifications

USA Patent Number 11,465,792

Canadian Patent 3,088,030

European Union Patent Pending

Length: 22 ft (264”) Long

Width: 8 ft (96”) Wide

Height: 10 ft (120”) Tall

Weight: 6000 lbs (2721 kg)

Power Supply: 125/250 V (30Amps) Single Phase